Precision Quadrupole Wound Fiber Gyro Coils

IFOG Coil Winding

———— Quadrupole Wet, Dry, Flanged, Hubbed or Freestanding

With a 7 year legacy of winding all types of precision optical fiber coils, Idealphotonics has the coil winding business unit with a team of highly experienced scientists, engineers, and winders, together capable of winding the best in optical fiber coils in accordance with customers' requirements. Cost effective and fast winding systems allow Idealphotonics to provide a complete range of products, from simple delay lines and payout spools to strategic quadrupole gyro coils of several kilometers in length.Also We provide optical fibers and then put them on the most appropriate stands whatever the material they are made of is (copper, aluminium, plastic…). We can also work without stand and realize optical fibers crowns. Otherwise, a wide range of optical fibers types (single-mode, multi-mode, PM, from UV to IR) and dimensions are available, a well as coating materials (polymer, polyimide…).Finally, we are at your disposal in order to meet your expectations and to solve yours problems as regards fiber optic coil winding, size and components integration among others.Our optical fibers spools lead to numerous applications in the fields of optical sensors, delay lines and fiber optic launch cables in particular.

Product Features

Complete Facility

|

|

| Automated Coil Winding Machine |

Quad Coil winding room in Yancheng |

|

|

| Extre high and low temperature testing | Testing facility in Seongnam |

|

|

| High precious Coil distributed Fiber Strain Tester |

Technical Specification

Coil Types

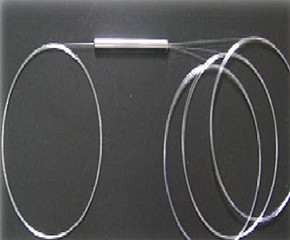

Depending on requirements a great number of stock or custom coil structures can be supplied. Designs from epoxy-potted, fully freestanding to totally constrained coils using pure or composite materials ensure environmental stability and ruggedness.

|

|

|

| Flanged – Wet or Dry | Hubbed – Wet Only |

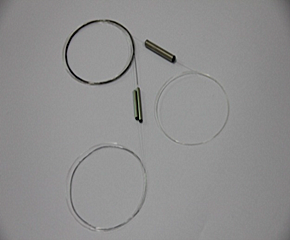

Freestanding – Wet Only |

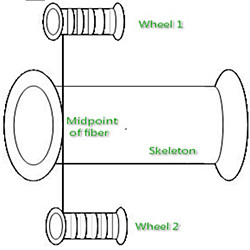

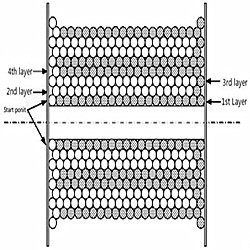

Typical Quadrupole Patterns

|

|

Quadrupole Wound Coil Attributes

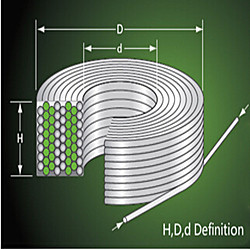

| Coil fiber Fiber Length :120 m ➞ 15km Fiber core diameter:13 mm ➞500 mm Fiber external diameter: 30 µm ➞ 600 µm Fiber tension: 20 g ➞ 2 kg Coating material :Polymer, polyimide, others Quadrupole Wound Coil Attributes Base Layer Turns :Up to 250 Layers :4 Layers ➞ 100 Layers Outer Diameter (D) :< 15 cm Inner Diameter (d) :> 1.5 cm Height (H) :< 5 cm Coil properlities Working wavelength:850/1310/1550 nm Crosstalk:<-18dB Attenuation:<1.0dB/km |

• Symmetrical coils for high degree of reciprocity |

Applications

CUSTOMER’S OEM REQUIREMENT

| Fiber type |

PM

1550/80-18/165 |

| Coiling method |

√ Quadruple screw |

| Fiber length |

515 m (including

pigtails)

4pcs |

| Turns per layer |

32 turns |

| Pigtail length |

4m each side |

| The reels |

Reels type ■ Free

standings coil |

| Reels size |

(diameter) 62 mm (width) 12.5 mm (height) 9 mm |

| Reels materials |

Aluminum Stainless steel Others |

| Coil tension |

5-10 g |

| Gluing |

■

Y N |

| Gluing type |

Gluing from the buyer; ■ Gluing from the seller with the coil specs; |

| Optical Index |

IL≤1.0 dB (Room temperature) PER ≥18 dB (Room

temperature) |

| Test report |

Test report for each coils ■(needed) |

Ordering

Information:

| PWC |

Xx(Wavelength) |

Xxx(Coating diameter) |

Xxxx(Coiling Method) |

Xxxxx-(coil length) |

6x-Pigtail Length |

7x-Structure |

| |

85:850nm |

135:135um |

Q:Quadruple |

400-400m |

1-1m |

F-Free standing |

| |

13:1310nm |

170:170um |

S:Screw |

800-800m |

2-2m |

B:Bobbin |

| |

15:1550nm |

250:250um |

|

1.1k-1100m |

3-3m |

|

PWC-13-165-Q-500-3-F:

Precision Quadrupole Wound Fiber Gyro Coils with operation wavelength 1310nm,PM fiber type 80/165um,Quadrupole winding method,coil length at 500m,Pigtail length 3m,with free standing structure

Precision Quadrupole Wound Coil Test report

© FOGphotonics, inc. | Company | Products | Technoloy | Contact us